The Quickest Order Sequencing for Smooth Production

Minimize risks in your production with extensive rule types in combination with interactive and automatic order sequencing. Smooth your production based on utilization, and record calculated dates in the integrated plant calendar.

This greatly reduces your planning effort and simplifies your daily work.

Already benefiting from SEQUIQ

With automatic sequencing, you get an optimal order sequence in seconds. Create meaningful reports directly in the software and use flexible interfaces to other systems in your company. This way, you can reduce the manual effort to just a few minutes.

Maintain complex requirements using extensive rule types and adhere to them easily with our automatic sequencing. A modern, user-friendly interface and clear and easy-to-understand visualizations help you to always keep an overview.

Identify bottlenecks early on and ensure the feasibility of your planning. Take into account the utilization of individual workplaces and use extensive rule types in combination with automatic sequencing to enable smooth production.

Increasing Complexity in Order Scheduling

The exploding number of product variants makes sequencing an extremely complex and time-consuming task. For you, this means stress, tight deadlines and uncertain production performance.

SEQUIQ helps you to master these challenges and reduce the time required to a minimum.

Data Maintenance

A Good Basis

Using extensive rule types, you can accurately represent practical requirements and goals within the software. For example, you can control density, sequence, or blocks of different orders. The integrated plant calendar also provides calculated deadlines.

Automatic Order Sequencing

Optimization at the Push of a Button

With our powerful algorithms, SEQUIQ automatically calculates the optimal order sequence in seconds based on the maintained rules. The plant calendar is also taken into account, and the deadlines in the optimized area are automatically updated.

Your Results

Greatly Reduced Planning Effort

Smooth Production

Master Complexity

- 100 – 2,000,000 Orders

- 10 – 1027 Order Variants

- 20sec – 4h Cycle Time

- 10 – 600 Stations

Does SEQUIQ Suit Your Production?

To ensure you get the maximum benefit from SEQUIQ, the key data of your production should fall within these parameters. Would you prefer to see which companies are already successfully using SEQUIQ? Explore our references.

Trusted by the World’s Leading Manufacturers Around the Globe

Over 5,000 enthusiastic users are already realizing the full potential of their production with SEQUIQ. This is the impact our software has on our customers worldwide:

12%

average increase in efficiency

50%

average decrease in time spent on planning

100%

more planning security

Find Out in 15 Minutes if We’re the Right Fit

Find out in an initial call whether our software is right for you. Together we will check whether and how much you can benefit from SEQUIQ in your production and planning. Clearly, quickly and without obligation.

- Gain clarity quickly as to whether our software is suitable for your production

- Free initial consultation and identification of potentials

- Follow-up appointment is tailored to your challenges

Develop the Future of Production Planning With Us

We have been concentrating on the further development of SEQUIQ for 15 years. With successful use by leading manufacturers and close exchange with our customers, the software is continuously optimized and adapted to the challenges of modern production planning.

- Benefit from continuous improvements driven by planners worldwide

- Receive updates tailored to your challenges

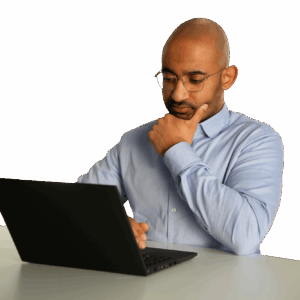

The Order Preview

Developed with BMW

Ensure quantities and smooth production through early detection of bottlenecks and better control of short-term capacity measures.

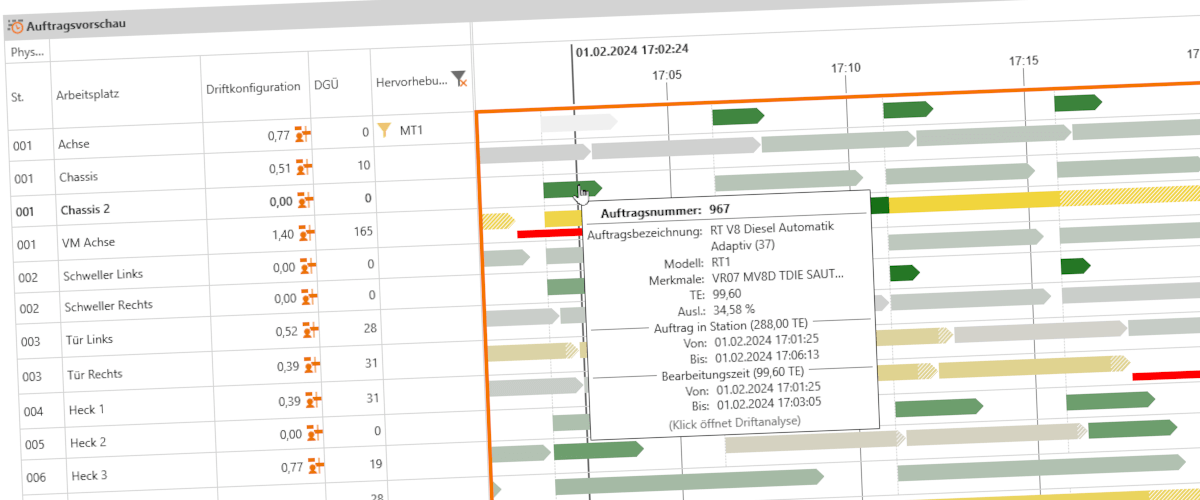

The Aggregated View

Developed with DAIMLER TRUCK

Get a clear overview of your orders by shift, day, week or month. This allows you to quickly see how well target deadlines are being met and how many orders of a certain type are being produced and when.

Regular Updates, Continuous Innovation

Close collaboration with our customers drives regular updates, making SEQUIQ an innovation leader. Explore the latest features and improvements in our YouTube playlist.

Click on the playlist icon at the top right of the video,

to see all the videos in the playlist directly.

All SEQUIQ Modules at a Glance

Expand SEQUIQ flexibly with our modules. Customize the solution to your individual production and achieve maximum benefit for your specific requirements.

Your Next Steps With SEQUIQ

Get to know SEQUIQ better and find out how you can take your production planning to the next level. Choose the way that suits you best.

Test alone

4-Week Free Trial

Test SEQUIQ for free and evaluate for yourself whether the software meets your requirements.

- Start in 5 Minutes

- Full Range of Functions

- No Risk

- Hands-On Experience

With Kira Askevold

Initial Call & Live Demonstration

Find out in an initial call whether SEQUIQ is right for you and then experience our software afterwards in a customized live demonstration.

- Clarity in 15 Minutes

- Expert Exchange

- Customized Live Demonstration

With Victor Küpper

Pilot Project or Requirements Analysis

Test SEQUIQ directly in your production environment with a tailored pilot project or on-site requirements analysis.

- Operate Alongside Current System

- Optimized Test Area

- Fit-Gap Analysis

- Tailored Training

- Personal Support